The System-on-Chip (SoC) Research Center and Institute of Electronics at NYCU have recently reported the development of a programmable biochip utilizing a standard CMOS technique.

This innovative semiconductor biochip provides basic functional modules, such as location sensing, microfluidic operations, temperature control, etc., in contrast to conventional techniques. As a result, bioprotocols for any target sample tests can be established in order to accomplish automation at a lower cost and in less time. It is also suitable for emerging applications, such as fast polymerase chain reaction (PCR) tests and cell quality assurance in cell therapy.

Brilliant Sensing Circuit Enhances Spatial & Temporal Resolution

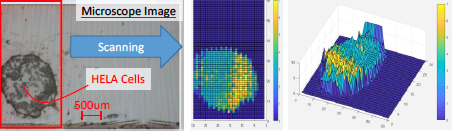

The capacitive sensing mechanism has been utilized in this biochip in order to detect and locate both the sample and reagent on the top of the biochip, based on the knowledge gained from the development of brilliant sensing circuits. In addition, by altering the sample phase, this biochip may easily determine permittivity differences across various materials.

Consequently, this biochip can be utilized for antibody and antigen assays in a highly effective manner. Moreover, the bit-plane images acquired from several sampling phases can be combined to create 3D sample profiling.

This technology, known as cell tomography, can be used to determine which cells or cell clusters are suitable for future culture in cell manufacturing. In addition, the proposed biochip can improve spatial and temporal resolution in order to cover a wider array of cell-biology applications.

Microfluidic operations play a key role in bio-experiments using conventional lab-on-a-chip solutions

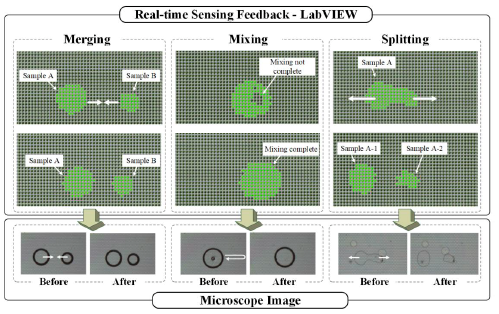

Using the electrowetting on dielectrics (EWOD) mechanism, researchers at NYCU have included a number of microfluidic operations (e.g., cutting, mixing, merging, transferring, etc.) onto this biochip. In addition, thanks to the innovative micro-electrode-dot-array (MEDA) architecture, multiple sample tests for microchannels can be simply programmed on the biochip.

As mentioned above, the location sensing capability and feedback loop control can be applied to monitor the droplet test procedure. Furthermore, since the biochip can be programmed to meet the requirements of different sample tests, not only accelerating the bio experiments but also contamination failure can be vastly reduced.

Part of the design automation of this biochip has been in collaboration with Prof. Krishnendu Chakrabarty from Duke University since 2015.

Microfluidic, Temperature or Thermal Cycle are Keys Factors for Testing Result

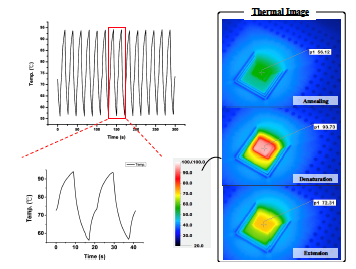

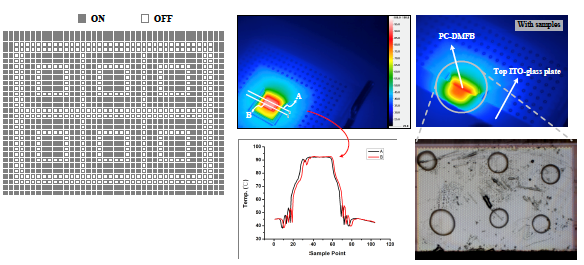

Temperature or thermal cycle control is an additional crucial aspect of medical tests, particularly PCR applications. Utilizing the same CMOS process technology, researchers at NYCU have integrated heating sources using digital control patterns to manage temperature profiles in a highly efficient manner.

Initial measurements indicate that the rate of temperature change can exceed 50°C/sec. In conjunction with the location sensing and microfluidic processes described previously, single and many samples can be readily managed on the biochip.

When battery-operated devices are taken into account, it is possible to precisely identify heating zones in order to satisfy thermal cycle requirements and improve energy efficiency.

Via 2D Digital Patterns on Biochip Research will Become Beneficial to Mankind

The functions mentioned above can be programmed via 2D digital patterns on the biochip. It could eventually lead to testing automation based on bioprotocols derived from target sample test procedures.

Prof. Chen-Yi Lee, the team leader, highlights that there will be more research opportunities ahead when multi-disciplinary teams are working tightly together. In addition, the research outcome will benefit society and pave the way to a better life with current/ongoing inventions and solutions.